Commercial Blower Door Testing for Optimal Building Performance

The Blower Door Test is a vital tool for assessing air tightness in large projects like commercial buildings, multi-family complexes, and other substantial structures. At Energy Incentives, Inc., we specialize in advanced blower door testing to identify where air leaks are affecting your building’s performance. By pinpointing and fixing these leaks, we help you cut energy loss, reduce utility costs, and improve indoor air quality. Our expert team is dedicated to ensuring your commercial building meets the highest standards of efficiency. We provide detailed analysis and actionable insights that enhance your building’s overall performance. You can trust us to deliver precise results that truly make a difference.

What We Do BEST

Expert Energy Auditing

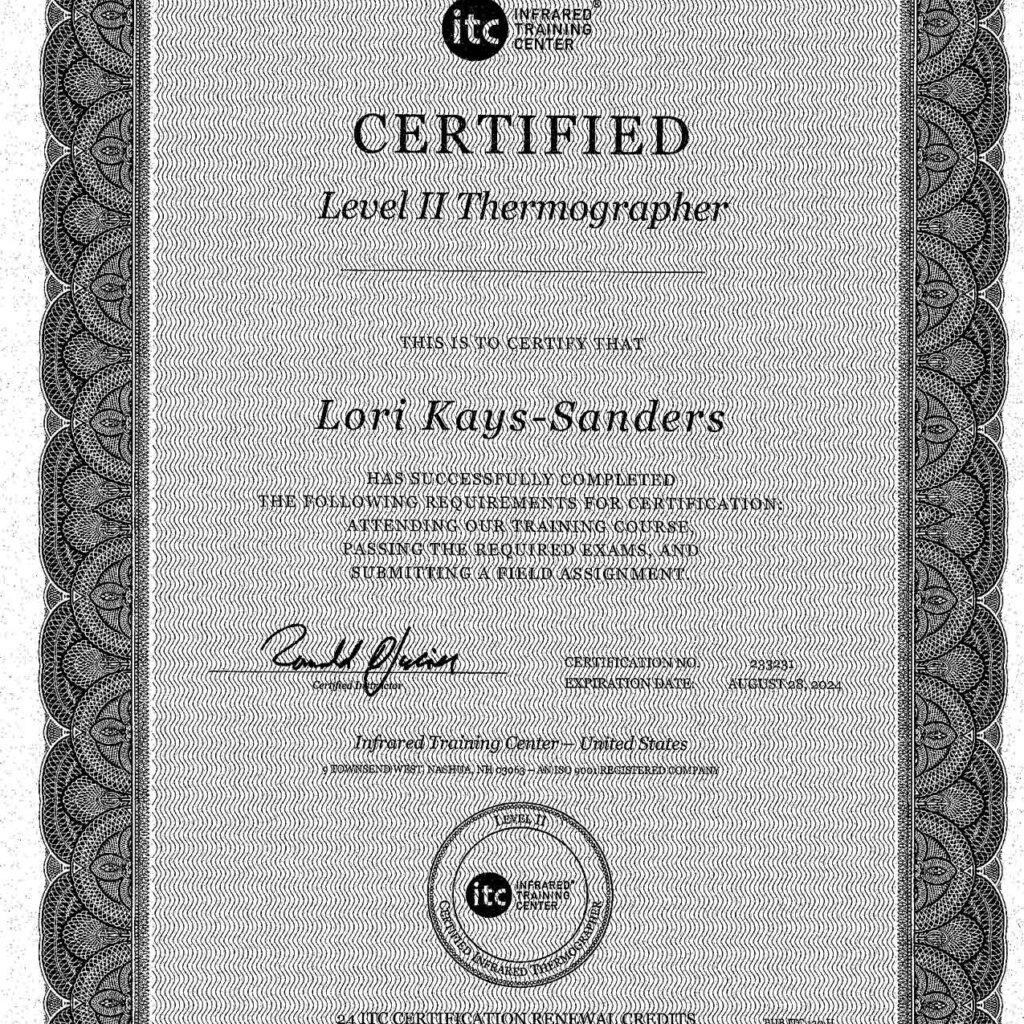

Our team, led by Lori Sanders, a certified Energy Star Rater and Level II Thermographer, conducts thorough energy audits to identify inefficiencies and recommend cost-effective improvements, ensuring your building operates at peak performance.

Comprehensive Air Barrier Testing

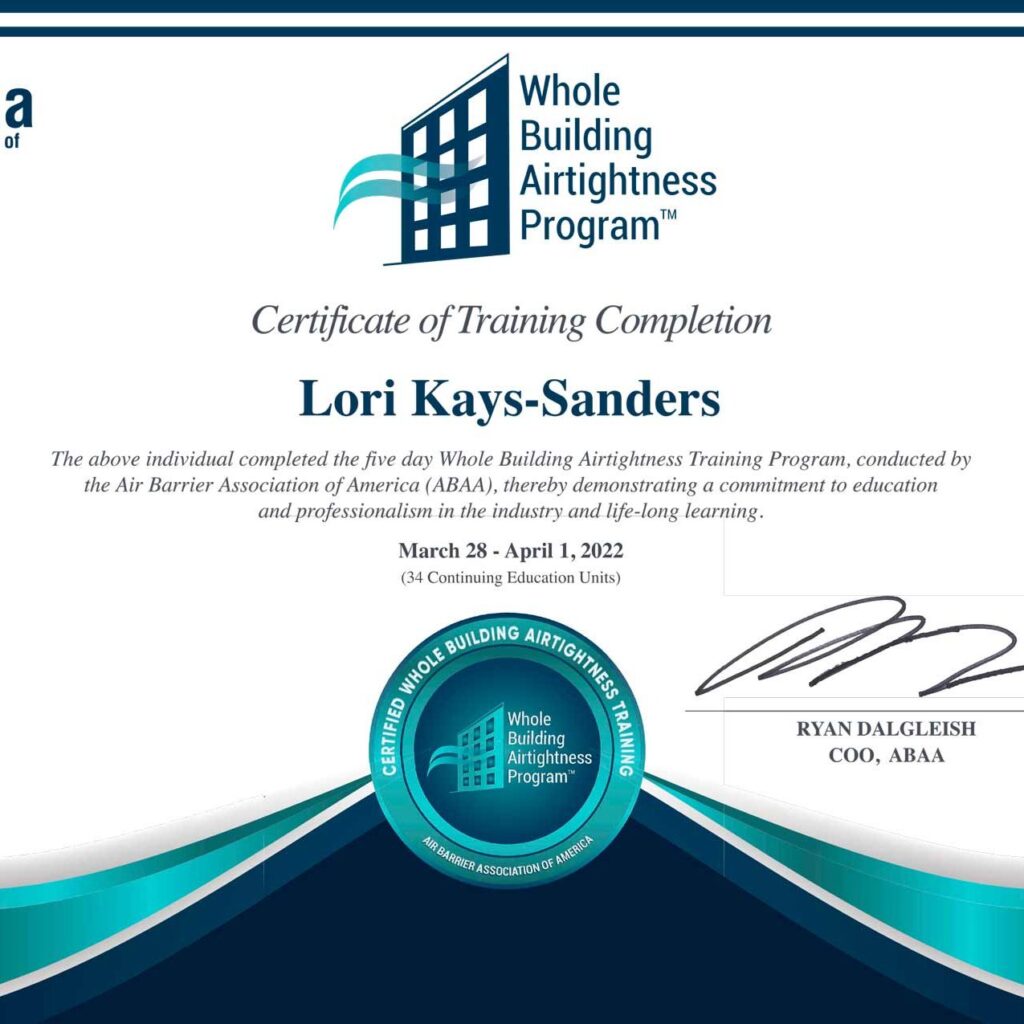

We specialize in precise air barrier testing, using advanced techniques like blower door tests and infrared thermography to pinpoint and resolve air leakage issues. Our certifications from ABAA and the Whole Building Airtightness Program™ underscore our expertise.

Tailored Energy Solutions

From consulting to implementation, we provide customized energy efficiency solutions that meet the specific needs of builders, architects, and developers. Our team holds top-tier certifications, including RESNET HERS Rater, LEED Green Rater, and Energy Star Multifamily New Construction, ensuring you achieve optimal energy performance and sustainability.

Achievements and Certifications:

Energy Star Partner of the Year: 2017, 2018

ABAA: Whole Building Airtightness Program™ Certificate of Training Completion

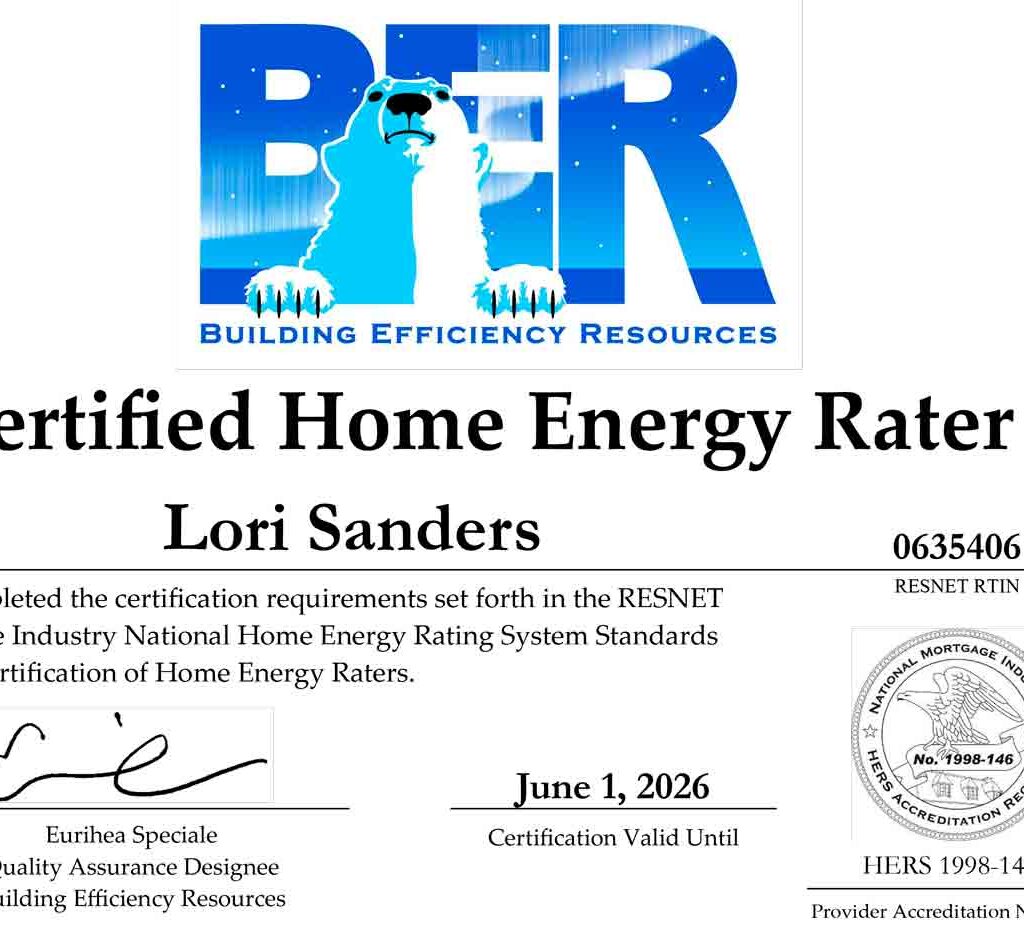

RESNET HERS Rater Certification: Residential Energy Services Network

Green Training USA: Certificate of Completion

LEED Green Rater: Training Certificate of Completion

ITC Infrared Training Center: Certified Level II Thermographer

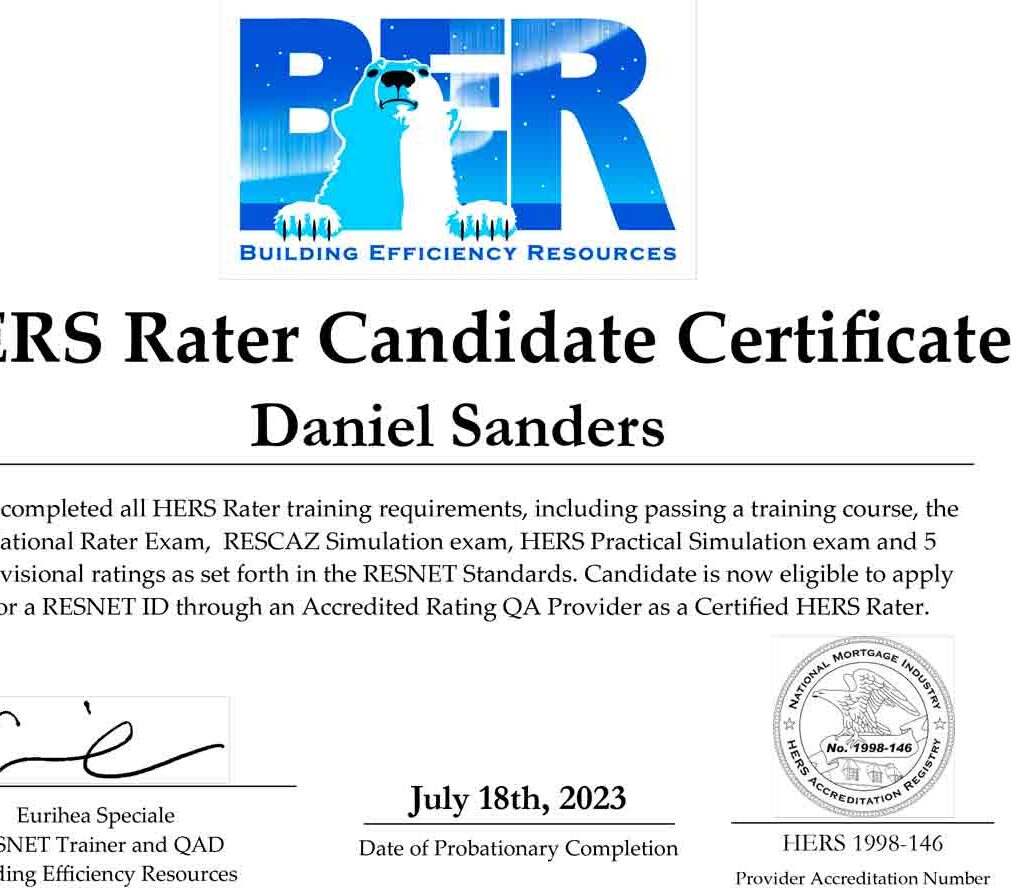

Building Efficiency Resources: HERS Rater Candidate Certificate

Energy Star Multifamily New Construction Version 1/1.1: Rater Training Course Certificate

These achievements reflect our commitment to excellence and continuous professional development, ensuring we provide the highest quality service to our clients.

Key Takeaways

Blower doors are essential tools for measuring a building’s airtightness by generating a controlled pressure difference to detect air leaks, helping to improve energy efficiency, indoor air quality, and overall occupant comfort.

The Minneapolis Blower Door System is highly regarded for its ease of setup, precise measurements, and advanced features, making it a preferred choice for HVAC contractors, weatherization professionals, and utility programs focused on energy efficiency.

Identifying and repairing air leaks through blower door testing can significantly reduce energy costs, enhance indoor comfort by eliminating drafts, and ensure compliance with strict building codes aimed at promoting energy-efficient construction.

Understanding Blower Doors

Blower doors are key instruments in determining a building’s airtightness. They work by generating a controlled pressure difference between the interior and exterior of a building, thus exposing otherwise undetectable air leaks. The primary purpose of a blower door test is to detect uncontrolled air infiltration and exfiltration through the building envelope, which can significantly impact energy costs and indoor comfort.

A blower door test employs a calibrated fan to measure the amount of air flowing out of the house, thereby determining its air tightness. This process not only identifies air leaks but also helps in assessing the overall efficiency of the building’s envelope. These tests are typically performed at the end of the building process, after retrofit work, or during an energy audit to ensure all improvements effectively reduce energy wastage.

Conducting a blower door test can lead to significant improvements in energy efficiency, indoor air quality, and occupant comfort. Finding and fixing air leaks enables homeowners to cut heating and cooling costs, improve comfort by getting rid of drafts, and tackle moisture-related concerns that could impact health. In essence, blower doors are a crucial component in the quest for more sustainable and comfortable living environments.

Components of a Blower Door System

A blower door system is comprised of multiple main components that synergize to accurately gauge a building’s airtightness. The core of the system is the blower door fan, specifically the Model 3 Fan, known for its flow measurements ranging from 300 CFM to 6,300 CFM. This single fan is crucial for creating the necessary pressure difference to test for air leaks.

Accompanying the fan is:

an adjustable aluminum frame

a durable nylon panel designed to fit various door sizes, typically up to 8 feet but customizable for other dimensions

a fan control cable

a USB communication cable

Together, these components make up a robust building airtightness testing system, essential for conducting accurate blower door tests.

Types of Blower Doors: Calibrated vs. Uncalibrated

There are two main types of blower doors: calibrated and uncalibrated. Each type possesses distinct attributes and advantages. For instance, calibrated blower doors come with gauges that record the volume of air exiting the house through the fan, thereby enabling contractors to measure air leakage both pre and post air-sealing enhancements. This quantitative data is invaluable for making informed decisions about necessary improvements and verifying the effectiveness of those changes.

In contrast, uncalibrated blower doors:

Merely locate leaks without supplying data about the home’s overall tightness

Are useful for identifying problem areas

Do not offer the same level of detail and precision as their calibrated counterparts

For those serious about improving energy efficiency and ensuring airtightness, calibrated blower doors are the preferred choice.

The Best Solution for Your Air Barrier Testing Needs in Washington State

At Energy Incentives, INC, we know how crucial air barrier testing is for your commercial building. It's not just about complying with Washington State's strict regulations; it's about ensuring energy efficiency, comfort, and health safety for everyone who steps through your doors. That’s why we use the Minneapolis Blower Door System—the gold standard in building airtightness testing.

Why Choose the Minneapolis Blower Door System?

The Minneapolis Blower Door System is recognized for its outstanding design and unmatched reliability. Here’s why it’s the best choice for your building:

Specialized Accessories and Testing Procedures

Specialized accessories coupled with advanced testing methodologies augment the precision and efficiency of blower door tests. The Energy Conservatory provides a range of specialized accessories for the Minneapolis Blower Door System, making it a preferred choice for various professionals.

These tools and testing procedures developed ensure that the testing process is thorough and reliable, delivering accurate results.

Optional Flow Rings

Optional flow rings are essential for achieving more granular measurement capabilities. The fan in the Minneapolis Blower Door System includes various-sized inlet rings to accommodate different levels of building envelope leakiness. By adjusting the size of the flow ring, testers can maintain a measurable pressure differential even in tight buildings, enhancing the accuracy of the test.

Flow rings like Ring D can measure air flows between 115 - 30 CFM, while Rings C, D, and E can measure flow rates as low as 11 CFM. These rings are modular, with designs such as Ring D being attached inside Ring B using fastener clips. This modularity allows for flexible and precise adjustments during testing.

Cruise Control Compatible Systems

Cruise control systems greatly simplify the testing process by enabling automated pressure adjustments. The Minneapolis Blower Door System includes a built-in Cruise Control feature for automated fan control, maintaining a constant pressure differential throughout the test. This automation ensures stable and accurate results, reducing the need for manual adjustments.

The Model 3 Fan’s variable fan speed control is compatible with solid state and cruise control, further enhancing the system’s functionality. The DG-700 gauge includes USB and RS-232 ports for automated tests and data logging, supporting energy raters and weatherization professionals in conducting fully automated blower door testing.

Utility DSM Programs and HVAC Contractors

Utility DSM programs and HVAC contractors heavily rely on blower door tests for energy efficiency improvements and compliance with building codes. These tests are often conducted both during and after construction or renovation to ensure the building meets energy efficiency standards. The Minneapolis Blower Door System is considered the system of choice for these professionals due to its precise measurements and advanced features.

HVAC contractors use blower door tests for:

Diagnostics

Verifying the effectiveness of air sealing and insulation improvements

Ensuring that all energy efficiency measures are properly implemented and effective

The advanced features of the Minneapolis Blower Door System make it an invaluable tool for these applications.

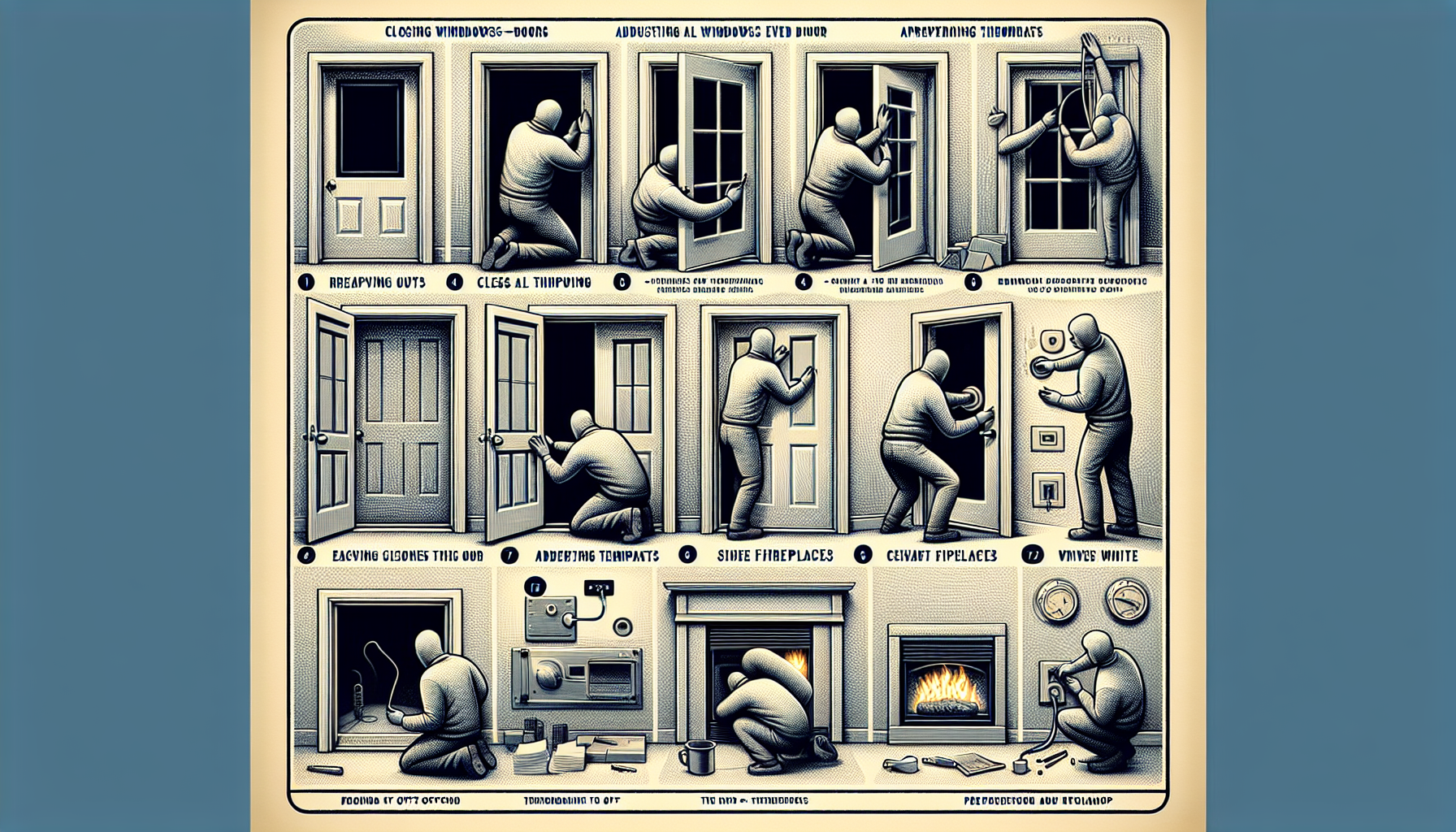

Preparing for a Blower Door Test

Adequate preparation is pivotal in guaranteeing precise results from a blower door test. Here are the steps to follow:

Close all windows to prevent outside air from entering and affecting the test results.

Close all exterior doors to ensure that the blower door can accurately measure the air tightness of the home.

Open all interior doors to allow the blower door to depressurize the home as a single unit, which helps in identifying leaks throughout the entire building.

It’s also important to turn off thermostats, air conditioners, and fans to maintain still air inside the home during the test. This helps in creating a stable environment for accurate measurements. Lastly, don’t forget to prepare the fireplace by closing doors, dampers, and air intake sites, and covering ashes with damp newspaper to prevent them from spreading during the test. These steps ensure that the test is conducted under optimal conditions, providing reliable data on the building’s airtightness.

Quick and Easy Setup

Fast Installation: This system can be adjusted and fitted into a door opening in less than five minutes, saving you time and hassle.

Professional Efficiency: Comes with a padded accessory case that keeps all the necessary tools protected and easily accessible.

Accurate Flow Measurements

Model 3 Fan: Includes Flow Rings A and B for precise measurements from 300 to 6,300 CFM, ensuring every corner of your building is tested accurately.

Durability: The fan housing comes with a 5-year ‘no questions asked’ warranty, showcasing its reliability.

Versatile Applications

Widely Trusted: Used by utility DSM programs, HVAC contractors, and weatherization professionals for its stable and accurate measurements.

Detailed Features for Superior Performance

Single Fan with Variable Speed Control

Precision Control: Adjustable speed control allows for exact adjustments during testing, whether manually or through a manometer.

Wide Range: Capable of measuring flow from 300 to 6,300 CFM, making it suitable for various building sizes.

Injection-Molded Fan Housing

Durable and Lightweight: This housing is rugged yet easy to handle, ensuring long-term reliability without added weight.

Adjustable Aluminum Frame and Nylon Panel

Versatile Fit: The frame fits a wide range of door sizes, from large commercial entries to smaller residential openings.

Custom Sizes: Available to meet specific needs, ensuring a perfect fit for any door.

Advanced Gauges and Measurement Tools

DG-700 Pressure and Flow Gauge

Dual Pressure Channels: Displays two independent differential pressures simultaneously.

Accurate Measurements: Bidirectional readings up to 1,250 Pa with auto-zeroing to eliminate sensitivity to orientation and temperature.

Time-Averaging Modes: Four modes for accurate measurement of fluctuating pressures.

Baseline Feature: Measures and records baseline pressure readings.

DG-1000 Digital Gauge

High Precision: Features advanced measurement and analysis tools with TECTITE Express 5.1 software.

Bluetooth Connectivity: Allows for seamless integration with other testing equipment.

Cruise Control: Built-in feature for precise and automated testing processes.

Comprehensive Measurement: Automatically calculates air changes per hour based on the building's cubic volume.

Importance of Air Sealing and Energy Efficiency

Air sealing and energy efficiency are essential in cutting energy costs, enhancing comfort, and adhering to building codes. By identifying and repairing air leaks, blower door tests play a vital role in enhancing the overall performance of a building.

The following subsections will delve into the specifics of identifying air leaks, the impact on energy costs and comfort, and the importance of compliance with building codes.

Identifying Air Leaks

Air leaks commonly occur through the outer walls, windows, doors, and other openings of a home. Identifying these leaks is essential for improving energy efficiency. Common exterior air leak points include exterior corners, outdoor water faucets, and areas where different building materials meet. Inside, air leaks can often be found around electrical outlets, switch plates, door and window frames, and baseboards.

Blower door tests are instrumental in pinpointing these leaks by pressurizing the home and detecting areas where air escapes. By depressurizing the home, these tests make air leaks easier to detect, allowing for targeted repairs that improve the building’s overall airtightness. Addressing these gaps and intersections can significantly enhance comfort and energy efficiency.

Impact on Energy Costs and Comfort

Air leaks contribute to higher energy bills by allowing heated or cooled air to escape, making HVAC systems work harder. Proper air sealing can prevent up to 40% of energy loss used for heating and cooling, while also improving air flow. This not only reduces energy costs but also minimizes the environmental impact of excessive energy consumption.

In addition to cost savings, addressing air leaks can significantly improve indoor comfort. Drafts from air leaks can make indoor environments uncomfortable, especially during extreme temperatures. Effective air sealing and insulation can maintain consistent temperatures, reduce drafts, and prevent moisture problems that can lead to mold growth over time.

Compliance with Building Codes

Adherence to building codes is critical to ensure homes satisfy strict air barrier test standards, thereby contributing to energy efficiency and overall building performance. The 2018 International Energy Conservation Code (IECC) acknowledges the need for either an air barrier test or visual confirmation of materials. The 2021 IECC requires an air barrier test with few exceptions, highlighting the increased emphasis on airtight construction.

Washington State has even more aggressive requirements, underscoring its commitment to stringent building energy codes. By meeting these standards, homeowners can ensure that their buildings are:

Energy-efficient

Compliant with the latest regulations

Providing added peace of mind

Offering long-term savings

Summary

In conclusion, blower doors are essential tools for measuring and improving a building’s airtightness, which directly impacts energy efficiency, comfort, and compliance with building codes. The Minneapolis Blower Door System stands out for its accuracy, durability, and advanced features, making it a top choice for professionals across various fields. By understanding the components and capabilities of this system, as well as the importance of proper preparation and air sealing, users can significantly enhance the energy performance of their buildings.

Investing in a high-quality blower door system, like the Minneapolis Blower Door, is a step towards more sustainable and comfortable living environments. Whether you are a homeowner looking to reduce energy costs or a professional aiming to provide top-notch services, the insights gained from blower door tests are invaluable. Embrace the power of accurate home energy testing and make a positive impact on both your wallet and the planet.

Frequently Asked Questions

What is the primary purpose of a blower door test?

The primary purpose of a blower door test is to identify uncontrolled air infiltration and exfiltration, which can affect energy costs and indoor comfort. Conducting this test can help address these issues.

What are the key components of a blower door system?

The key components of a blower door system consist of a calibrated fan, an adjustable aluminum frame, a nylon panel, and advanced gauges for precise testing and measurement. These components work together to assess a building's airtightness effectively without any additional context.

Why are calibrated blower doors preferred over uncalibrated ones?

Calibrated blower doors are preferred over uncalibrated ones because they provide quantitative data on air leakage, allowing contractors to measure and verify the effectiveness of air-sealing improvements. This ensures a more accurate and thorough assessment of overall tightness of a building.

How does the Minneapolis Blower Door System enhance testing efficiency?

The Minneapolis Blower Door System enhances testing efficiency through its ease of setup, high measurement accuracy, and advanced features like variable speed control and cruise control, making it a preferred choice for accurate and efficient testing.

What steps should be taken to prepare for a blower door test?

To prepare for a blower door test, make sure all windows and exterior doors are closed, open interior doors, turn off thermostats and fans, and prepare the fireplace by closing doors, dampers, and air intake sites. This will help ensure an accurate and effective test.

Our Reviews

Michael H.,

Facility Manager